The Ultimate Guide To 24hr Media

Table of ContentsThe Single Strategy To Use For 24hr Media24hr Media for BeginnersThe 2-Minute Rule for 24hr MediaThe Facts About 24hr Media RevealedWhat Does 24hr Media Mean?

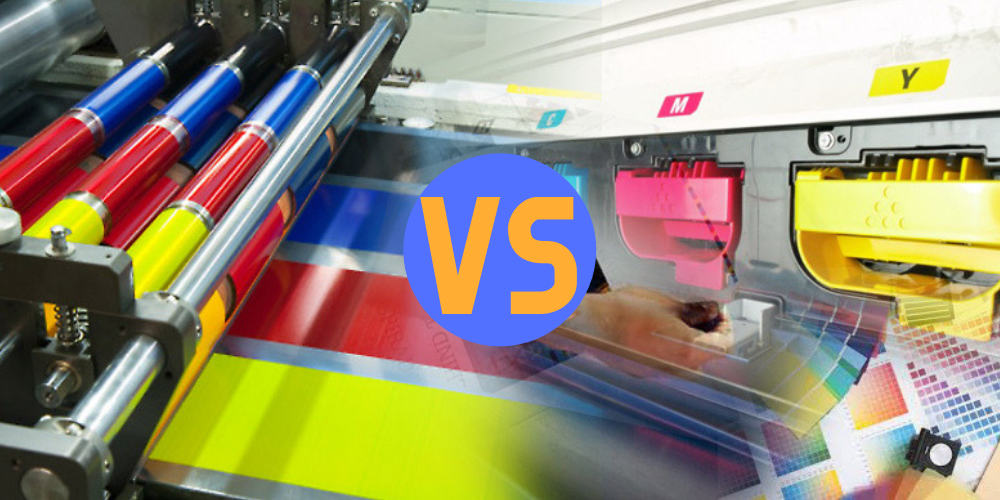

Innovations in print modern technology are transforming the interactions playing field when it comes to top quality, price and sophisticated abilities. Balanced out printing and digital printing are the significant procedures by which print work are undertaken both making use of four-color printing techniques. Each option has its benefits, using different techniques to fulfill the requirements of diverse production tasks.

Commonly, this has actually been one of the most regular strategy for specifically keeping shade suits, making it suitable for print runs that just need static printing such as pre-printed forms, brochures, flyers, calling card, and bulk postcard mailings. However, due to the fixed nature of litho printing, it is not ideal for variable print items that will certainly be mailed to individual recipients such as statements, letters, and personalized postcards.

24hr Media Can Be Fun For Everyone

The most up to date improvements in print technology are assisting to bring much of offset's advantages right into the electronic printing world absolutely changing the face of modern printing! There are some crucial distinctions between Offset Printing and Digital Printing (Wallpaper). This overview reveals the advantages and drawbacks of each printing approach. There is an indisputable and expanding variety of advantages to utilizing the electronic print procedure.

Today's digital print equipment is among one of the most cutting-edge on the market. Here are some of the most significant advantages of utilizing digital printing: control the electronic print room, with full-color printing finished in one process and flawlessly published straight from a print data. Without a lengthy set-up process, the calibration time of a specific work is reduced, adding to quicker print time and general shipment.

The inkjet printing process has helped to change the sector along with the top quality and rate of the outcome. The newest inkjet technology can publish on typical countered stocks with boring, silk, and glossy finishes. Top quality digital print paired with software-managed color administration techniques includes maximum worth to print items and makes production processes extra reputable than balanced out.

Not known Details About 24hr Media

(https://www.kickstarter.com/profile/1318309029/about)

Green and eco-friendly inks and toners are also available for even more sustainable printing. Digital print also gets rid of the demand to wash plates or blankets with harmful chemicals at the end of the printing procedure.

Variable information helps businesses reach their specific clients and audience with uniquely-created and personalized content. As technology boosts, the high quality of digital printing has actually ended up being second-to-none, with greater information, color suit abilities and total accuracy. Without the need to clean plates or utilize excess ink, electronic printing is likewise much less wasteful and usually a lot more eco-friendly.

("flexo"), entail multiple make-ready steps to move an initial image to a substrate.

Some Known Incorrect Statements About 24hr Media

While electronic printing is a sensible alternative for most short-run print jobsspecial events, prototyping, or other considerationsits contemporary capacities truly receive rapid turn-arounds. Having the ability to tailor product packaging via variable information printing has actually opened brand-new chances for you to engage with your clients in more customized methods. Digital printing, with fewer moving items, is extra agile than countered hereof.

Decreased set-up time saves cash on the front end. And considering that these are not large bulk orders, smaller sized services can afford to publish without having to satisfy the higher and a lot more expensive print limits of conventional printing.

Be sure you team up with a printing and product packaging partner that has the best certifications. While eleventh-hour printing and modification are a significant benefit, electronic may not constantly be the most effective approach for you. Balance out printing has the benefit of cost-effectiveness with large print runs, specifically those with advanced ornamental results and specialty layers.

24hr Media Things To Know Before You Get This

The positive plate, with its smooth surface area, draws in oil-based inks and fends off water. In contrast, the adverse plate, with its rough texture, absorbs water and pushes back oil. Rubber rollers are then utilized to move the photo from the plate to the corrugated surface.

Corrugated paper can often show to be a tough surface to print her comment is here on, yet Litho prints to a separate surface area and is after that laminated to it, making it very easy to publish premium images. It can be incredibly regular, even for long terms. As a matter of fact, the more you print, the more affordable the costs become for Litho.

If you have adequate time and budget, and a large volume of a solitary layout, after that there shouldn't be an issue. What Litho doesn't provide you is specifically what Digital does, customization. A lot more on that particular later on. Pricey set up Longer turnaround No Variable Data Printing Smaller sized color gamut, shades can be much less brilliant Digital printing is the procedure of printing electronic images directly onto the corrugated substrate utilizing a single-pass, direct-to-corrugate strategy - Digital Printing.